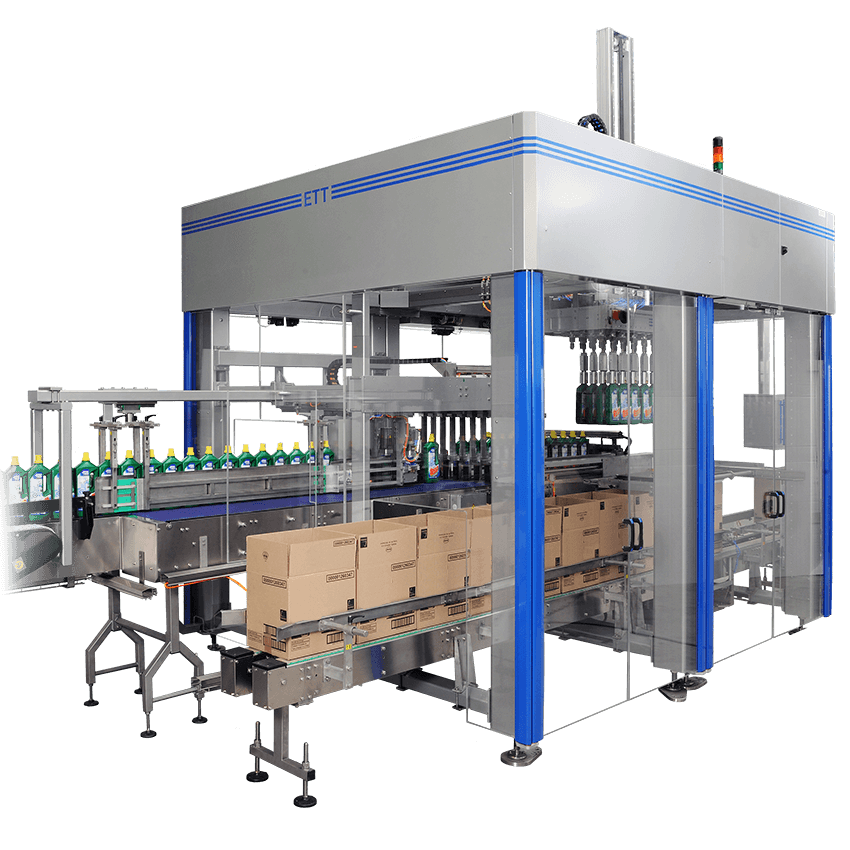

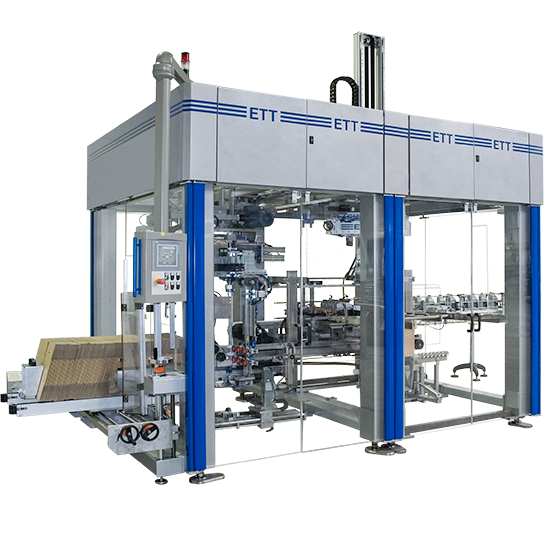

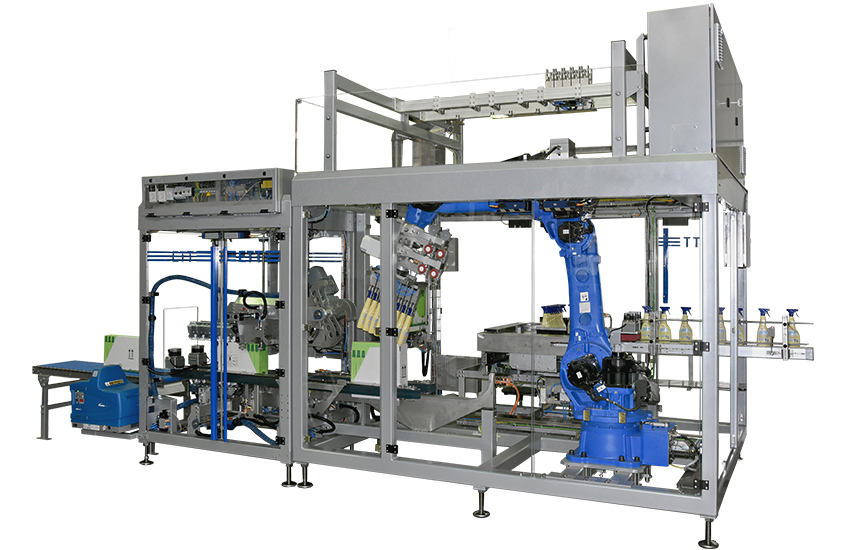

CONVENTIONAL CASE PACKER

Highest flexibility

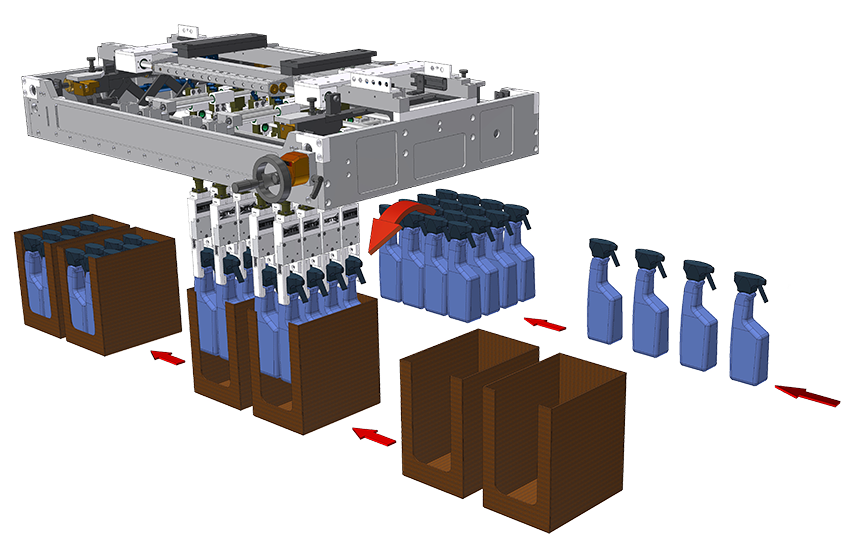

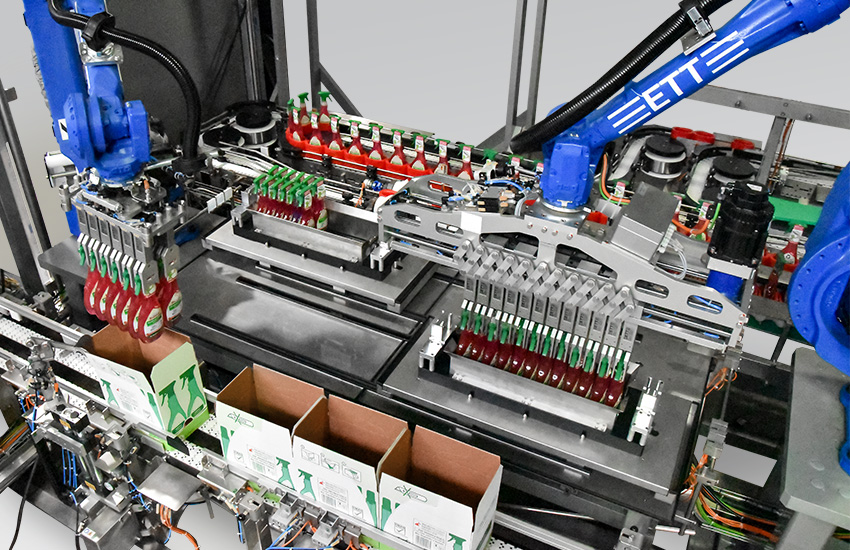

Thanks to its rugged welded frame and the integration of custom-tailored collating units and gripper systems as well as customised conveyor equipment, this conventional packaging machine offers numerous possibilities for use – it can handle almost everything!