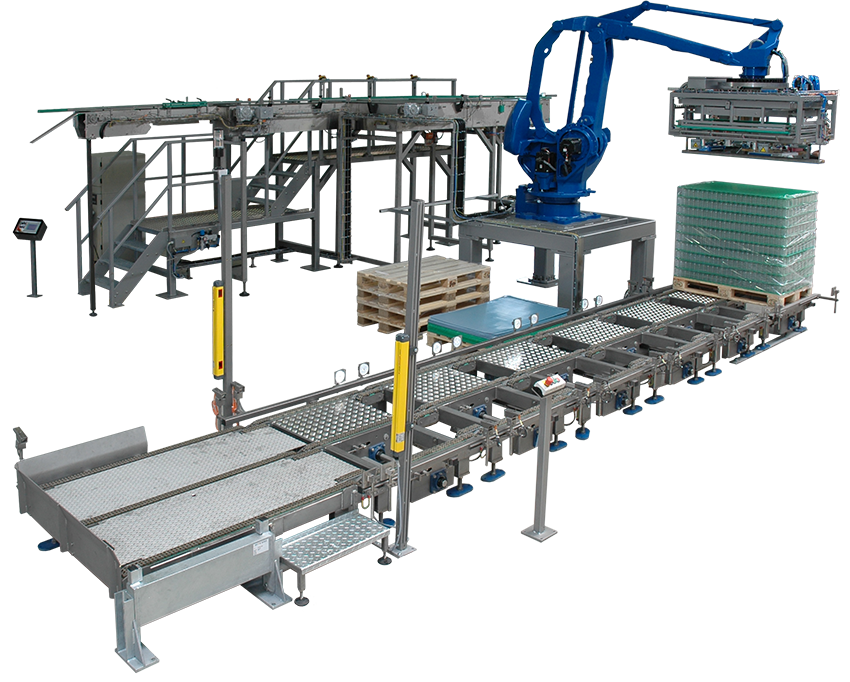

ROBOT DEPALLETISING CELLS

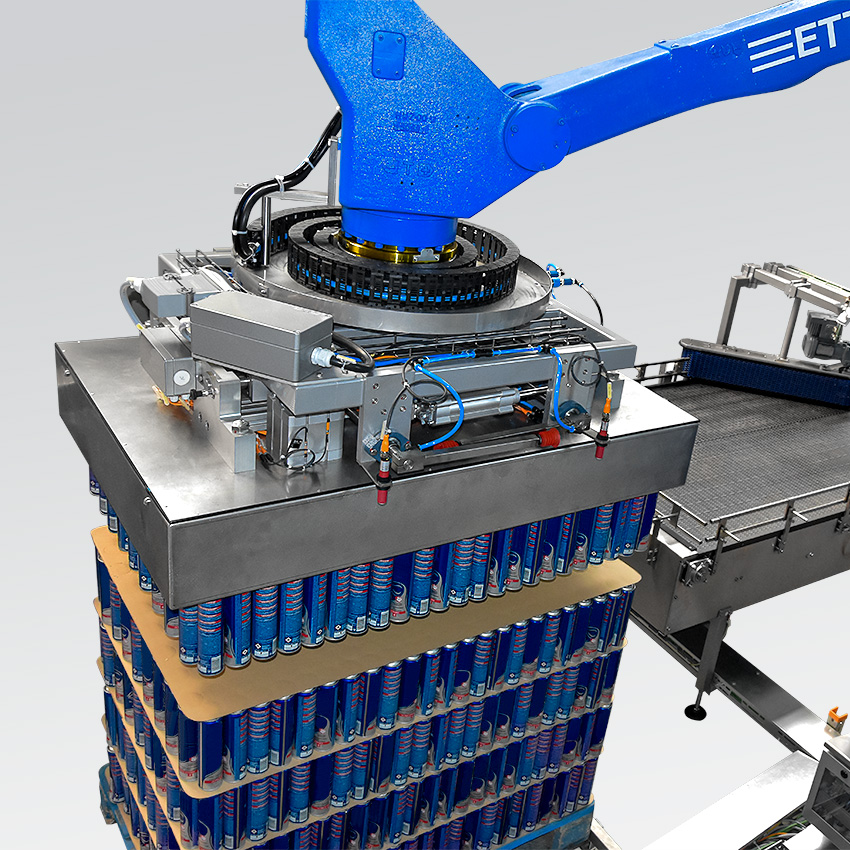

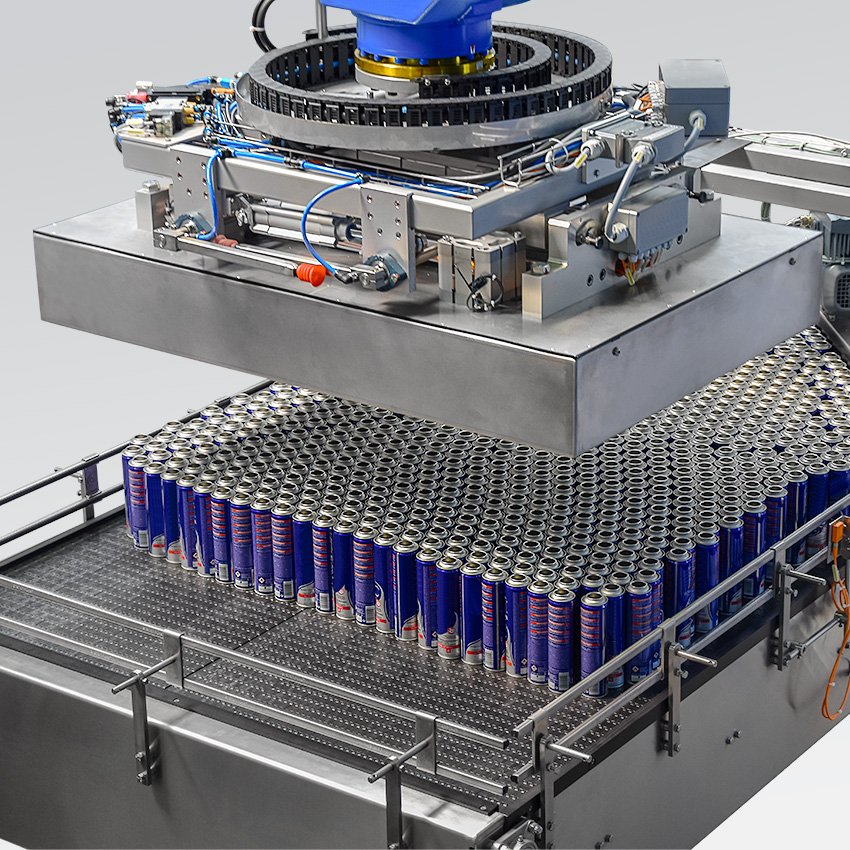

The head makes the difference

The state-of-the-art PLC systems of the depalletiser ensure ease of operation and high flexibility in production. In addition, the depalletiser offers high process-reliability and ease of changeover to different product sizes, thanks to its gripper head designed and made by ETT, while keeping maintenance costs and energy consumption at low levels.

Whereas large containers (e. g empty canisters) are usually depalletised row by row, unstable products such as empty cans require a different approach. For these products, we delevoped an electromechanically controlled layer gripper head for reliable and gentle product handling. This head unloads a complete layer from the pallet and places it onto a layer table for separation. When choosing the perfect gripper system, the size of the product as well as the positional accuracy on the pallet are decisive factors. ETT’s experts will find the perfect solution for your needs.