YOUR EXPERT FOR PACKAGING Machines

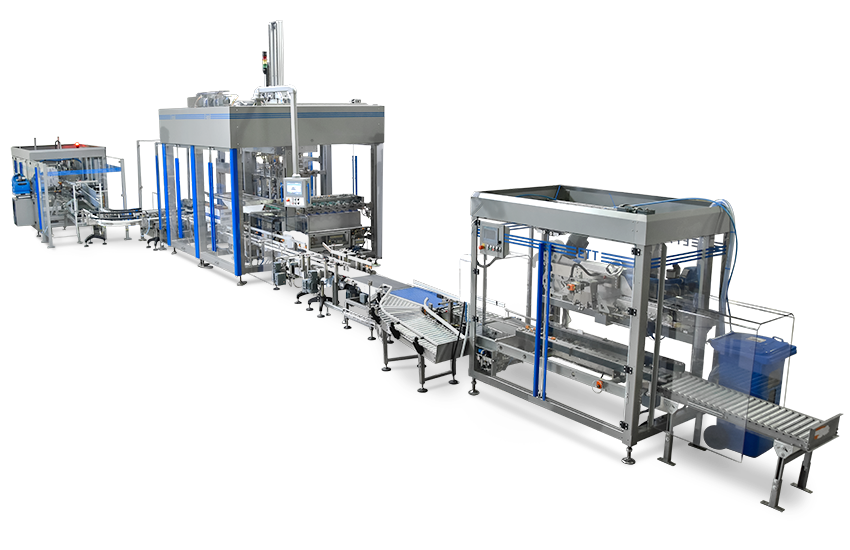

Packaging is subject to the pressure of logistical challenges, promotionally effective design and ease of handling. With our packaging machines and system modules for automated end-of-line packaging, we are able to offer you high-quality and state-of-the-art solutions with great potential for rationalisation and cost optimisation.

Forming and preparing of cases, collating, picking and case loading of products, sealing and palletising of cases and preparation for dispatch – all these steps can be automated with packaging machines by ETT.

The individual requirements of our customers can be met by use of modular standardard packaging machines. Their design can be customised to satisfy almost every packaging need. Our in-house design engineering, component production, installation and commissioning give us the flexibility needed to cover this wide range of services. The different departments work hand in hand, from conception and implementation to the delivery of the packaging machine.

Case former

Before the product can even find its way into the case, the cardboard blank has to be opened and tightly sealed at the bottom. ETT’s tray and case formers do this job in a fast and reliable process.

Packer

The powerful modular top loading robot is the central element of each ETT packaging system. Tried and tested state-of-the-art drive technology ensures fast and precise case loading of a wide range of products.

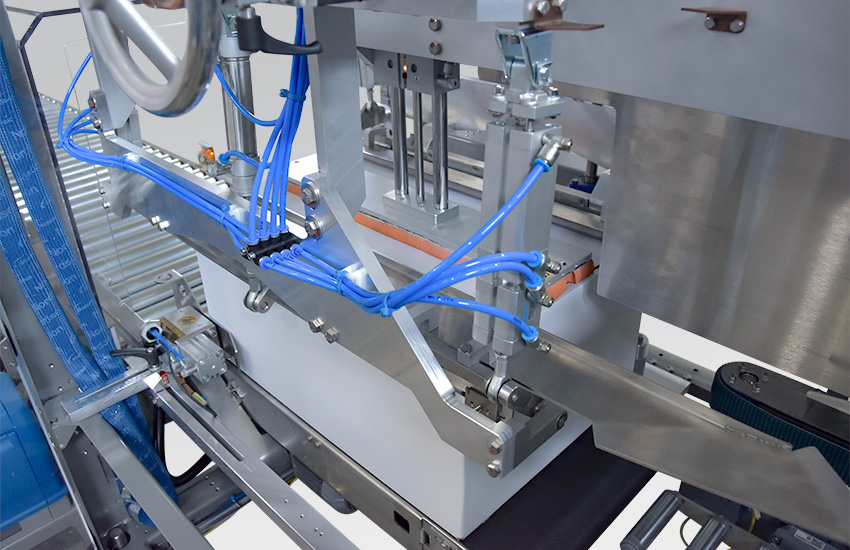

Sealer

The sealer is one of the last stations in the end-of-line packaging process, before the goods packed in cases get on their way to the customer. Whether using hot glue or tape – the packed case has to be tightly sealed before leaving the end-of-line packaging machine.

Concealer

The lidder places a lid on the filled case to prepare it for dispatch to the retail trade. Thanks to their universal design, the ETT lidders can handle both U-lids or cover trays.

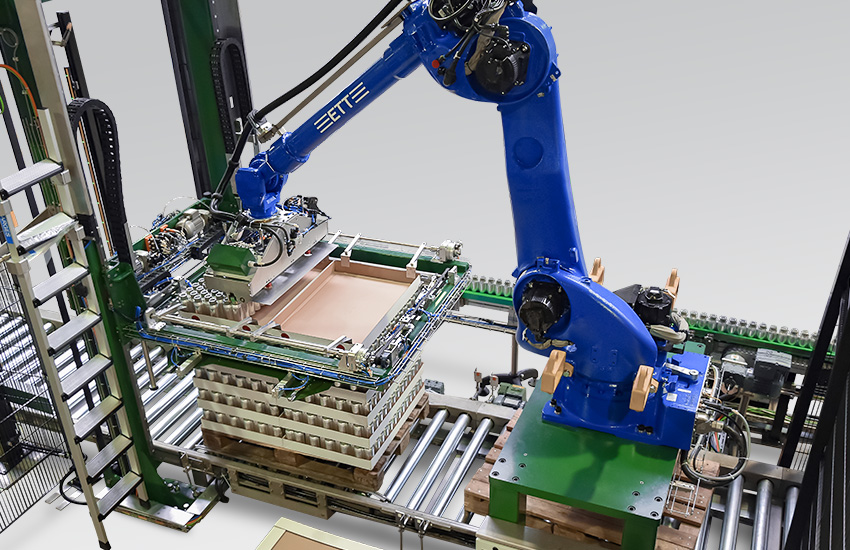

Palletiser

The palletisers stack the finished cases onto the transport pallet to ensure that your goods remain safe and undamaged during transport.

Forming, packing, sealing and even palletising - an all-in-one solution based on standard modules can cover all these steps to automate you entire end-of-line packaging process.

FAQ

The product has already been filled/packed into a primary packaging such as a bottle, can, tube, bag, cardboard box, etc. The packaging machine loads the product in its primary packaging into a secondary container such as a tray, an RSC case, or a wraparound case. This transport or final packaging is required to make the product transportable and to protect it during transport.

For ETT, a packaging machine or cartoner is a machine that loads products into a secondary / transport packaging such as a tray, an RSC case, or a wraparound case. The typical speed range of such a machine is 80 to 360 products per minute or 7 to 60 cases per minute respectively. A packaging machine can handle a great variety of products. The changeover to different product sizes can be performed manually, semi-, or fully automatically.

Gantry pick-and-place packer (top-loading)

A pick-and-place packer uses Y-Z gantry axes to load the products from above into the formed transport case.

Robotic pick-and-place packer (top-loading)

This pick-and-place packer is based on a robot with 6 axes to load the products from above into the formed transport case.

Side loading packer

This packer loads the products to be packed from one side into the formed transport case.

Wraparound

A wraparound packer wraps the transport case around the products and closes it. In the first step, the products are pushed onto the flat case blank. In the next step, the left and right walls or front and rear walls of the case are folded up. In the final step of the process, the top side of the case is folded down and glued, so that the transport case is completely closed after these folding sequences.

Product or size changeovers can be performed manually by adjusting setting wheels, replacing forming tools, changing insert strips and case guide rails on the packaging machine. Many of these adjustment processes can be automated by means of motorised drives. The automatic adjustment of rail positions, gripper head settings or automatic gripper head change are standard practice in product and/or size changeover procedures.

Basically, each product needs to be checked for its suitability for an automatic packaging process. Typical points to be checked are the dimensions, form, weight and also the material of the primary packaging. In principle, even products such as plastic bottles or pouches made of recycled materials can be handled by a packaging machine.

A sorting system is used to compile a desired assortment of products in a transport case. An assortment can consist of several products that have to be compiled in a specified ratio, e. g. products P1, P2, and P3, packed in a six-pack case at a ratio of 3 to 1 to 2.

MAKE A NON-BINDING ENQUIRY NOW

ETT are looking forward to implement your project in close cooperation with you. Send us a non-binding enquiry, our team would be pleased to give you advice.